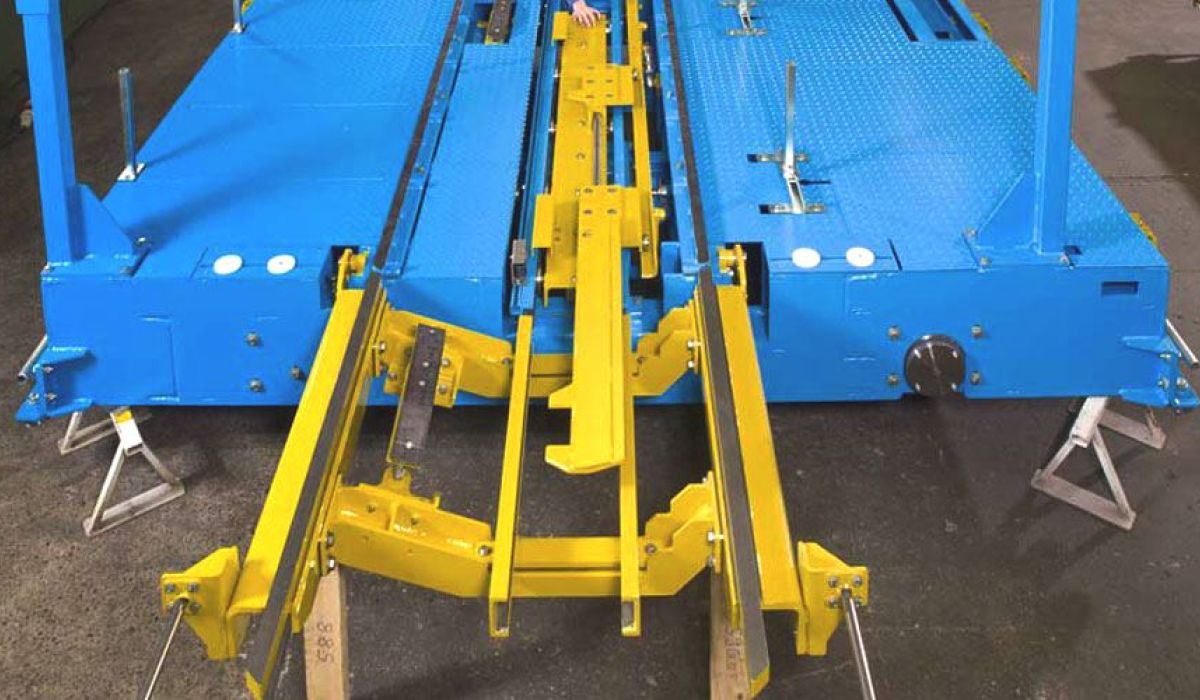

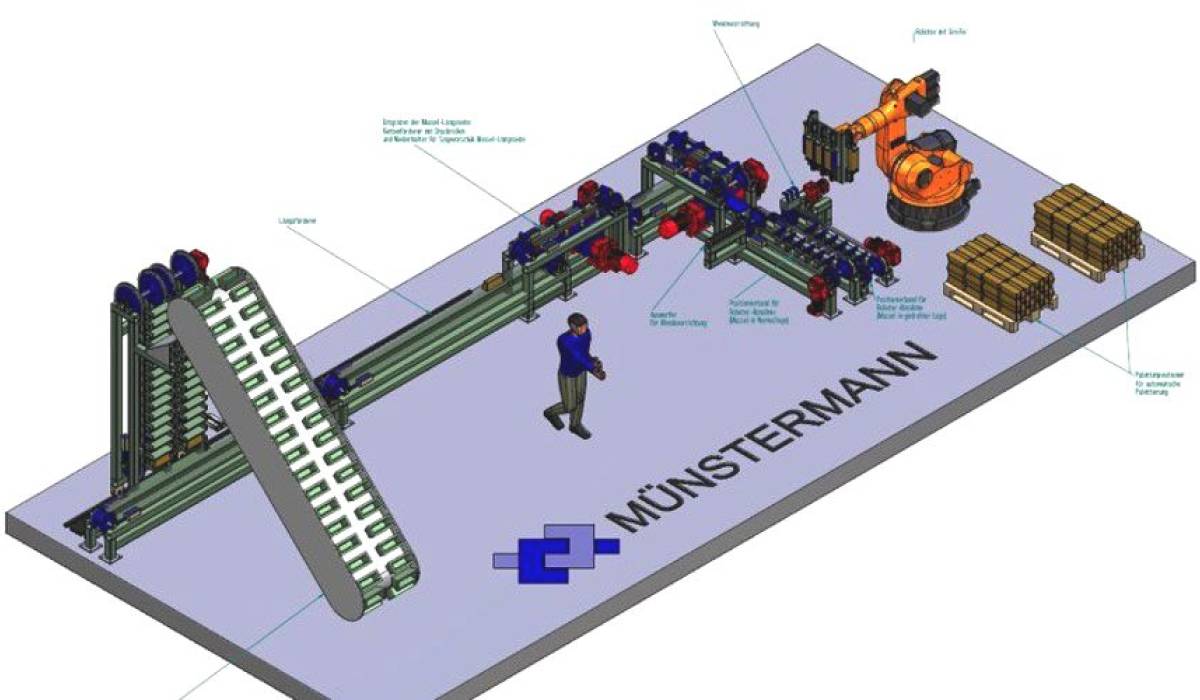

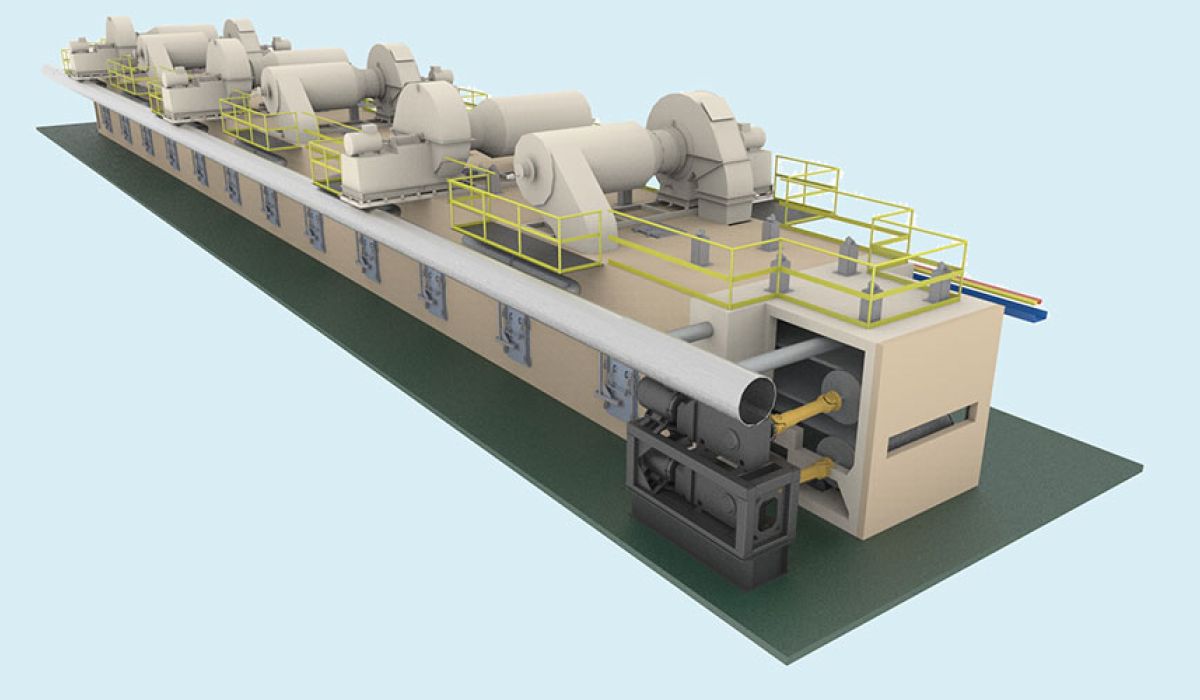

Projects material handling Steel construction and drive technology for a transfer car

Sometimes we are especially happy about a project. The reason for this can be an exciting application, a special challenge or the fact that the customer comes from the neighbourhood.

Read more …